- CTP wastewater treatment equipment

- Light guide plate equipment

- Automatic Sticker Machine

- Non - Standard Automation Equipment

- Connector Industry Automation Equipment

- Fully Automated Production Lines

- Test Fixture Series

- Tooling Carrier Series

- The first division (standard machine)

Contact information

DongGuan MSA Intellingent Technology Co.,LTD

Contact: Mr. Cai

Mobile:13650018949

Contact: Mr. Zhang

Mobile:13809627148

Tel:0769-81111739

Fax:0769-81621070

E-mail:msamg@msasmart.com

Website:ygjs666.cn

Add:1st Floor, Yunding Technology Innovation Park, No. 22, Farm Industry Road, Dalingshan Town, Dongguan City

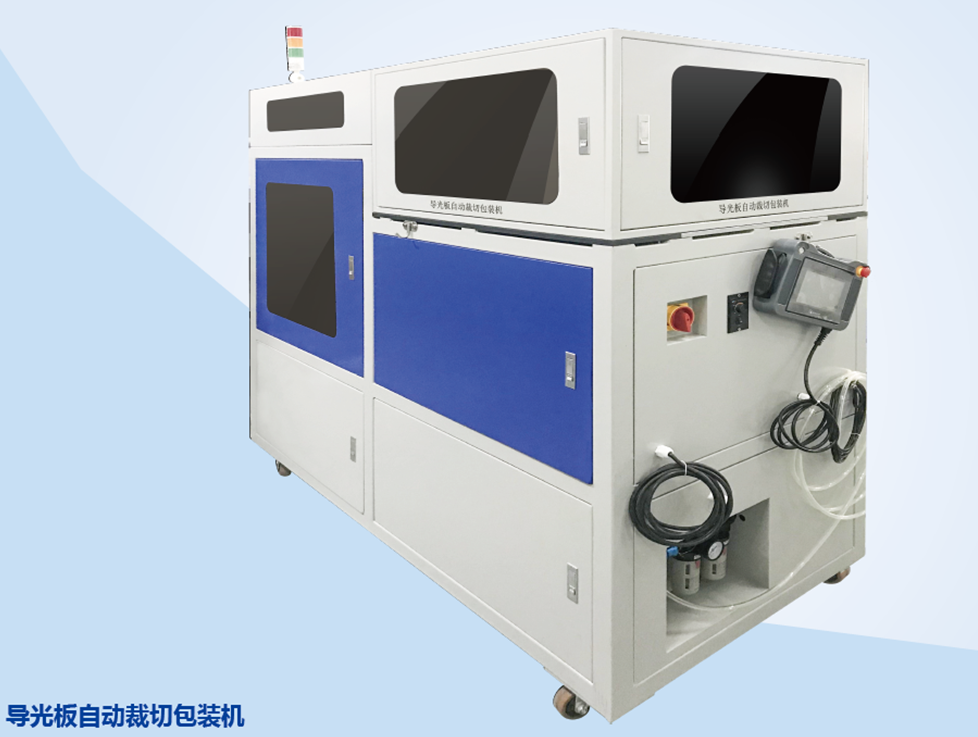

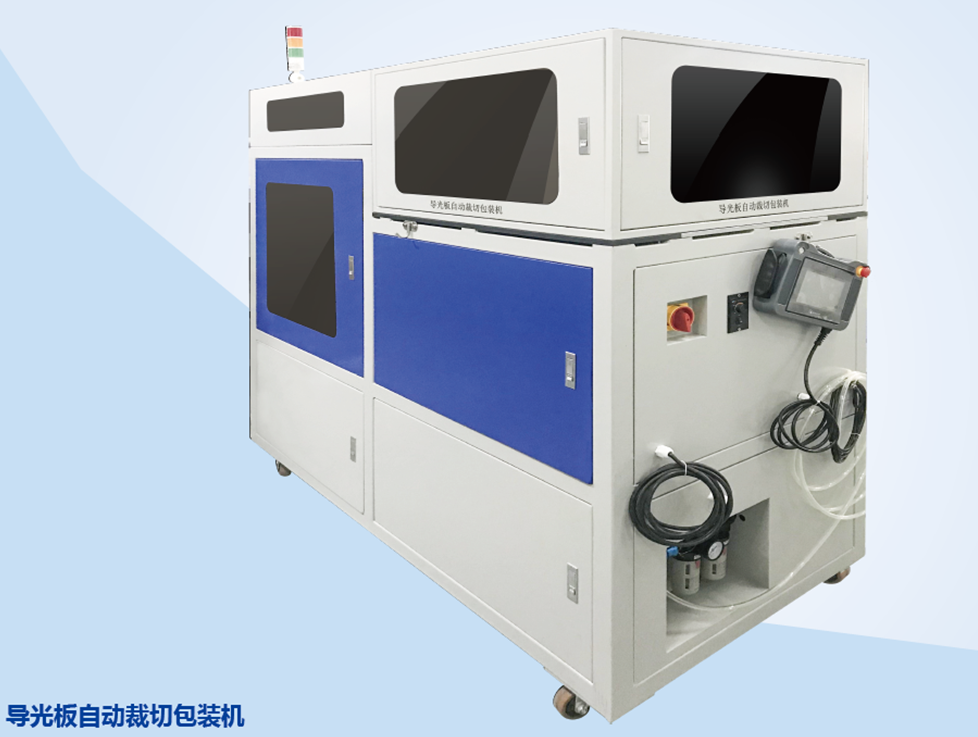

- Product Categories:Light guide plate equipment

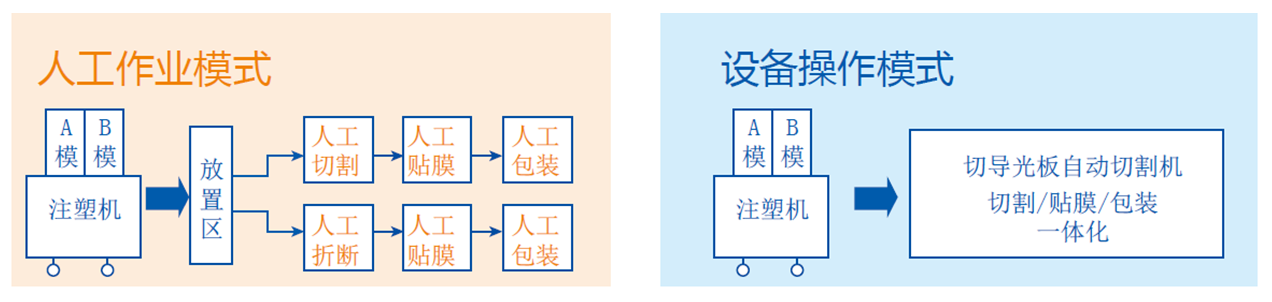

It uses the optical grade acrylic/PC board, the light guide board design principle originates from the notebook computer liquid crystal display screen, is the high-tech product which transforms the line light source into the surface light source. After years of development, the light guide plate injection molding has become more and more mature, but the process after injection molding is limited by technical restrictions and processing requirements, in the recruitment of difficult, difficult to retain people, poor quality stability, staff wages, welfare benefits continue to improve and the quality of customers are getting higher and higher still using manual cutting (or breaking) manual packaging is no longer available. The law satisfies today. ..

Based on the above pain points, MSA hired German August August and Japanese Professor Yamada in 2016 to jointly develop a small size light guide plate automatic cutting and laminating machine. After two years, with the efforts and efforts of all partners, MSA developed the process and obtained invention and new practical patents. It replaces human work, saves manpower for factories, improves efficiency, and eliminates the quality problems associated with products.

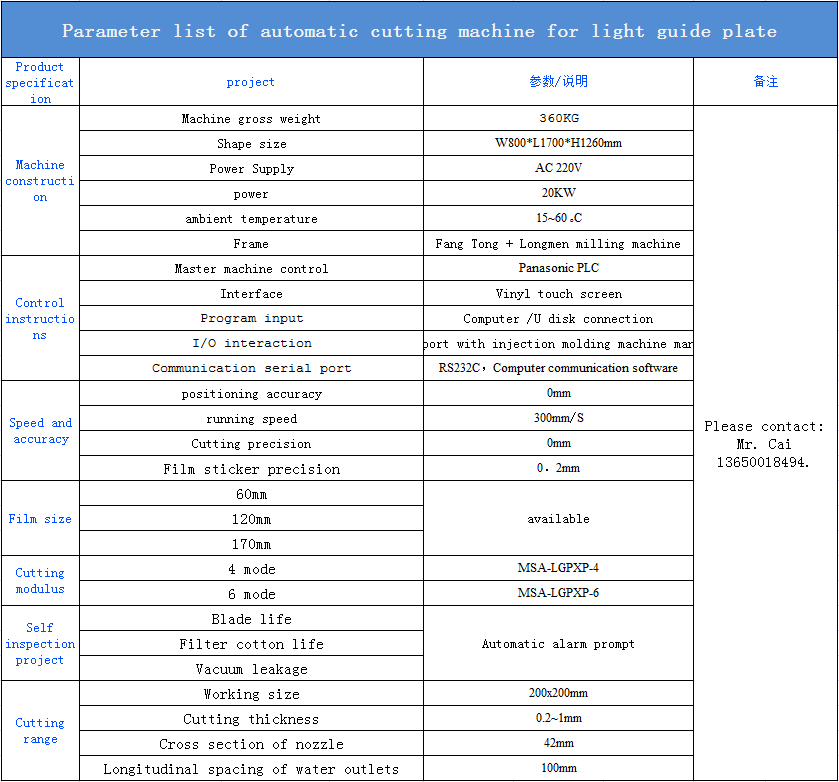

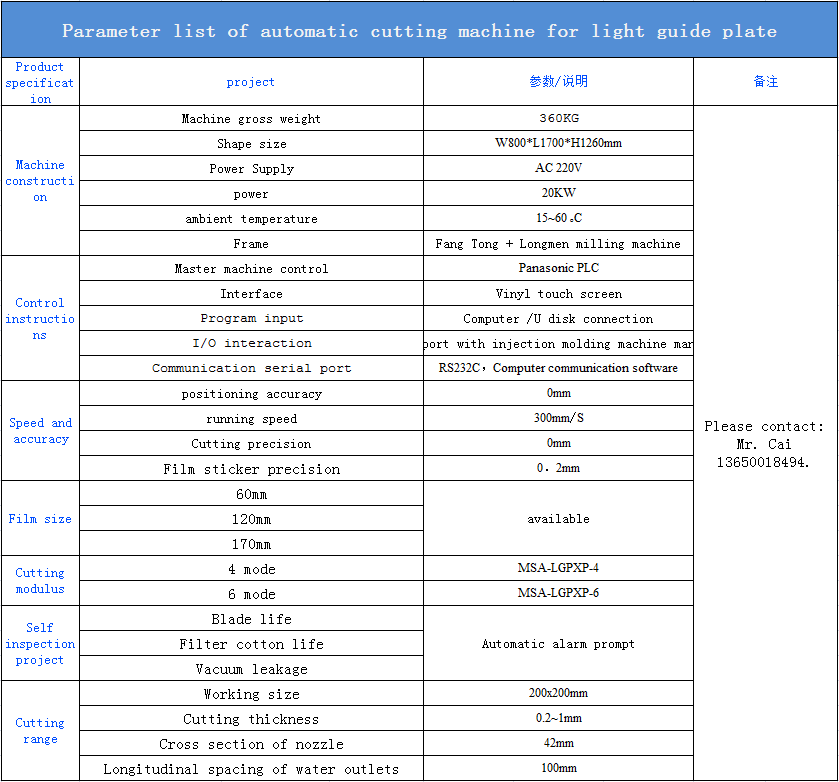

The technical features of automatic cutting machine for light guide plate are as follows:

1. Structural highlights:

(1) The frame is made of national standard square pass combined with gantry milling, which ensures the stability of the frame and the horizontal and vertical degree of assembly.

(2) the design is simple and practical, and can be quickly on-line and mastered.

(3) The interface takes full account of the convenience of on-line use, the interface is rich and easy to organize, and each interface is designed with anti-daze.

(4) the translucent brown PC is used in the institutional windows, which is superior to the atmosphere and is convenient for monitoring the internal working conditions.

(5) Module and famous brand pneumatic parts combined with soft software, and 0 tolerance cutting accuracy and stability of versatility, follow-up expansion space, high repetition accuracy, good film quality and so on.

Two, electronic control (software) highlights:

(1) Adopting Panasonic 6-axis PLC, the program runs stably and reserves upgrade space for the follow-up function of automatic swing Tyay.

(2) The whole circuit provides various protection functions, such as leakage protection, undervoltage protection, external interference filtering, overvoltage and overcurrent protection, which not only protects the safety of personnel but also fully protects the machine itself.

(3) In the design of software parameters, all kinds of complicated situations are fully considered, from external communication to internal control. Various flexible and reliable parameter settings are set up, which are simple, easy to understand and easy to understand.

(4) The system also has two modes, automatic and manual, which can improve the functions and reduce human errors.

(5) Take full account of the management of strong and weak electricity to ensure the safety, stability and reliability of electricity in wiring and wiring.

(6) With error information self-correcting diagnostic system, the equipment can self-diagnose faults in the process of operation, troubleshooting, timely resumption of production.

(7) monitoring tool life management to avoid tool life exceeding standard and cutting down a large number of products.

(8) Adopt negative pressure down-suction structure, low-pressure high-speed mute fan, super-strong suction, solve the dust impact on the product, achieve small space, low noise

(9) Modular control system, with very high stability, using patented technology cutting accuracy to achieve 0 tolerance, to meet the requirements of light guide plate cutting, to ensure the quality of production. Modular electronic control system, troubleshooting fast.

Facilitate the later maintenance and upgrading of equipment.

(10) Patented cutting technology, extremely low space occupancy and strong stability, fast, high-precision cutting speed

About after sale:

One year warranty, life-long maintenance (except for vulnerable parts)

In order to create a famous brand enterprise, improve its popularity and establish its image, we sincerely promise to you on the principle of "the most favorable price, the most considerate service and the most reliable product quality" in the spirit of "all pursuit of high quality and customer satisfaction".

First, product quality commitment:

1, quality inspection and testing data are available for manufacturing and testing of products.

2. To test the performance of the product, we invite the user to check the whole process and all-performance of the product personally, and then pack the product and ship it after it is confirmed to be qualified.

Two, product price commitment:

1. In order to ensure the high reliability and advanced nature of the products, the components are selected domestic or international high-quality brand products.

2. Under the same competitive conditions, our company will offer you the most favorable price sincerely on the basis of not reducing the technical performance of the products and changing the components of the products.